Managing DEF Risk with DEFGUARD™ system

As of 2014, new diesel refuelers are equipped with Selective Catalytic Reduction (SCR) system that requires Diesel Exhaust Fluid (DEF) to help meet exhaust emission regulations. Refuelers with the SCR systems are widely used in the general aviation market. Fueling operators are now required to maintain DEF in their fueling operations in addition to FSII/PRIST anti-icing additives. Other than the containers they are stored in, DEF and PRIST are indistinguishable from each other as they are both colorless and odorless solutions.

DEF is not an approved additive for jet fuel. The composition of DEF includes 32.5% urea and 67.5% de-ionized water. Unfortunately, urea is not soluble in jet fuel. When DEF is injected into jet fuel, the urea falls out of the solution in crystalline form. These crystals can cause flight safety risks as they can plug up on-board fuel injection systems. Once DEF contaminates FSII injection systems and on-board fuel systems, it becomes impossible to remove the urea crystals. Tens of millions in damages have resulted. In some recorded cases, the entire aircraft must be deemed unflightworthy.

Source: NTSB (2022)

How big of a risk is DEF?

According to the latest Federal Aviation Administration (FAA) General Aviation Reports, the FBO network in the United States includes:

- Approximately 3070 FBO's operating at 3016 airports

- Approximately 6000 refueling trucks

- 40 % require DEF

- 75 % have FSII injection systems

- 1800 refuelers with potential exposure to DEF issues - 4,5 million jet fuel fuelings

- 75 % containFSII/PRIST

- 75 % use on-board additive injection system (2,5 million fuelings)

Source: NTSB (2022)

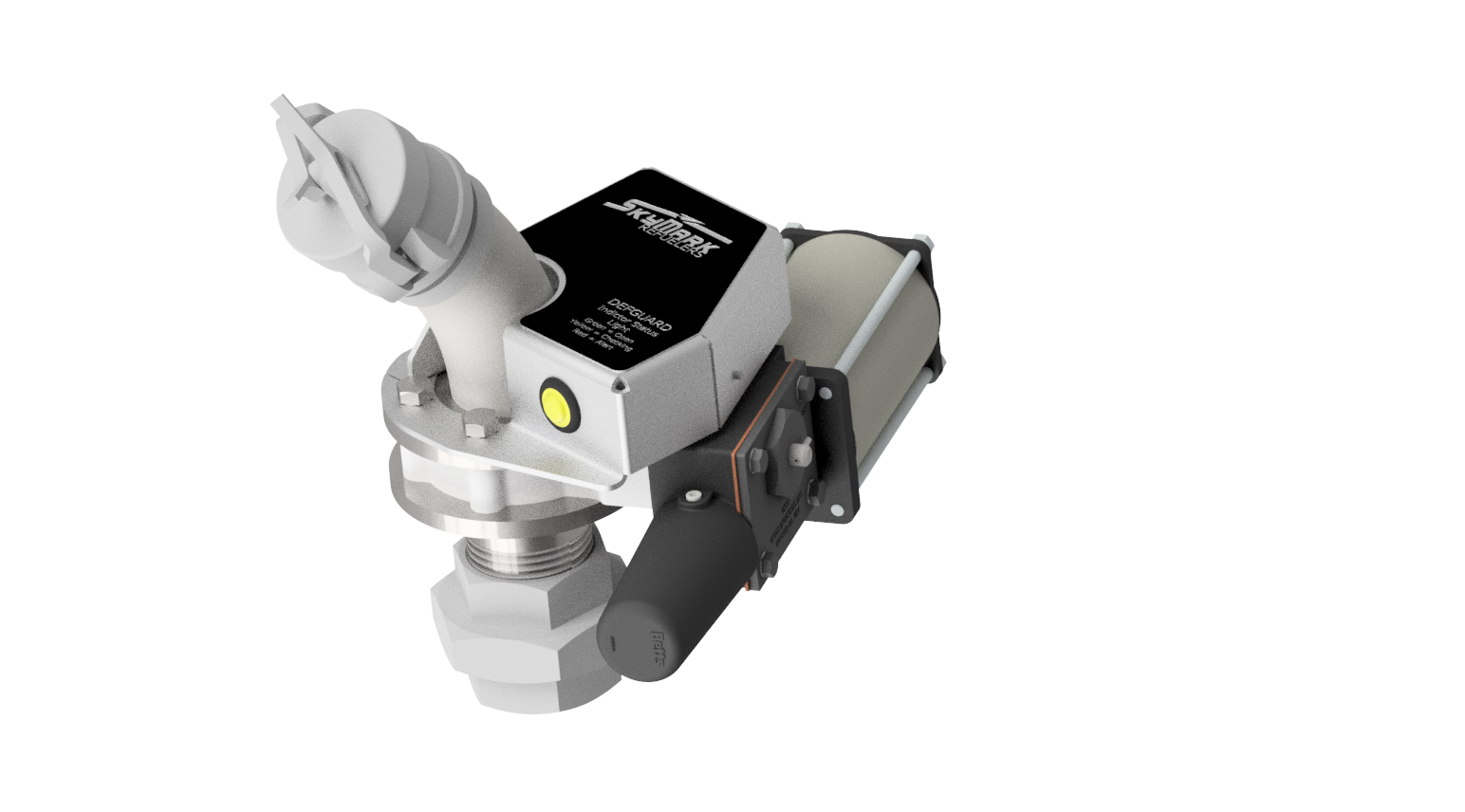

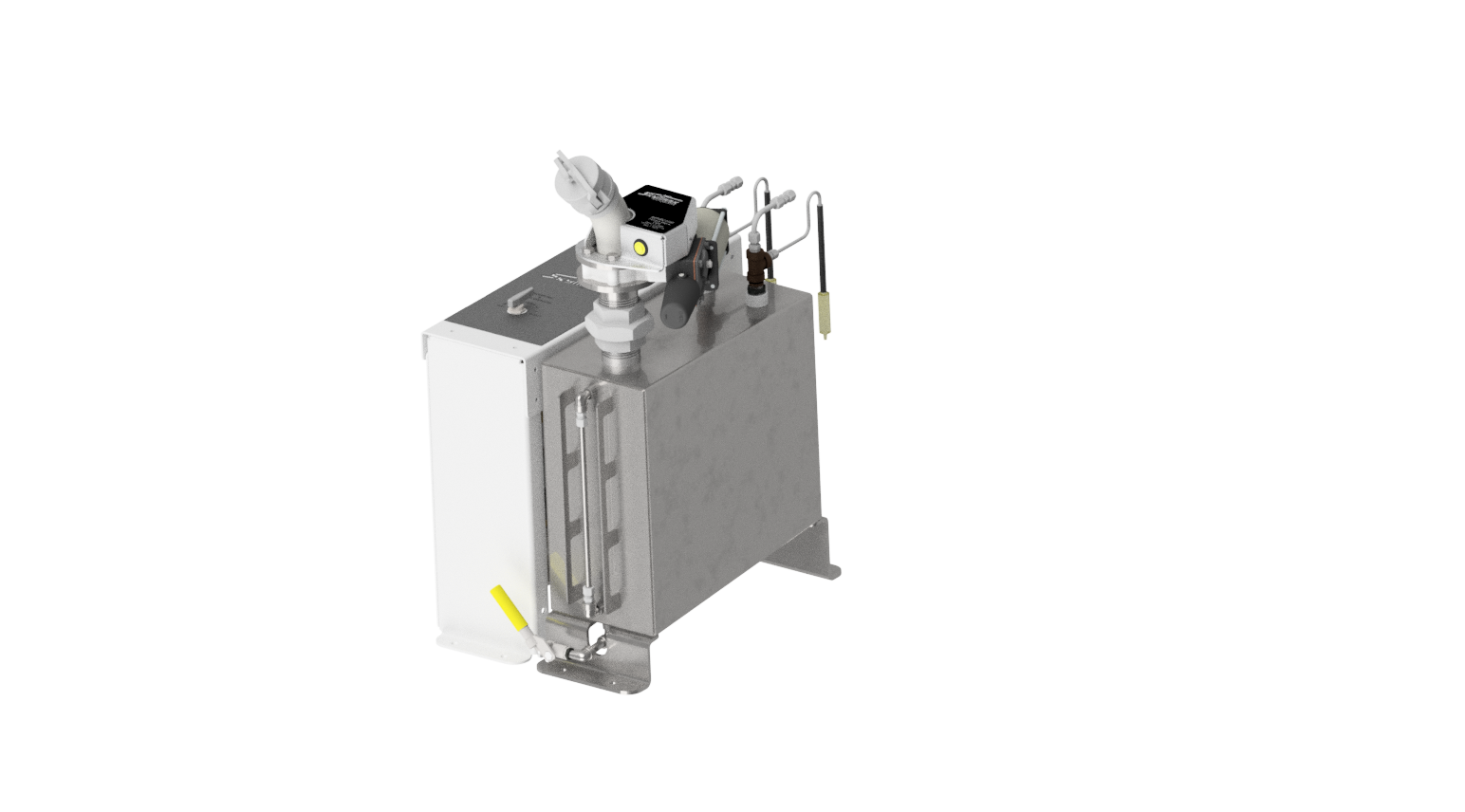

DEFGUARD™-system

FAUDI Aviation America and SkyMark Refuelers have collaborated to develop an innovate engineered solution called the DEFGUARD™. When included as part of a safety regime, the DEFGUARD™ system can halt the introduction of DEF into the FSII injection. The unique smart nozzle system is designed to detect when gross amount of DEF is poured into the FSII storage on your refueler. Its unique configuration with multiple sensors keeps the fill nozzle normally closed until FSII is detected. If other bulk fluids such as DEF enter the nozzle, it will stay closed to prevent fluid contaminating the reservoir and signal the warning light.

Features and Benefits:

- Protects FSII-Tank from DEF contamination

- Drops to safe closed position

- Prevents human errors

- Can be integrated into PLC system

- Consistent availability of the system

- Cost effective by eliminating expenses for chemical test disposals

- Electronic based detection assures accurate detection

- Retrofit kit for existing refuelers

Specifications:

- Repeatability and Quick Response Time

- Operating Temperature: -40 °C to + 85 °C (-40 °F to 185 °F)

- IP67 and IP67K (with appropriate cable)