Filter Vessels

Extensive portfolio of high-quality vessels for filtration and separation of contamination in fuels.

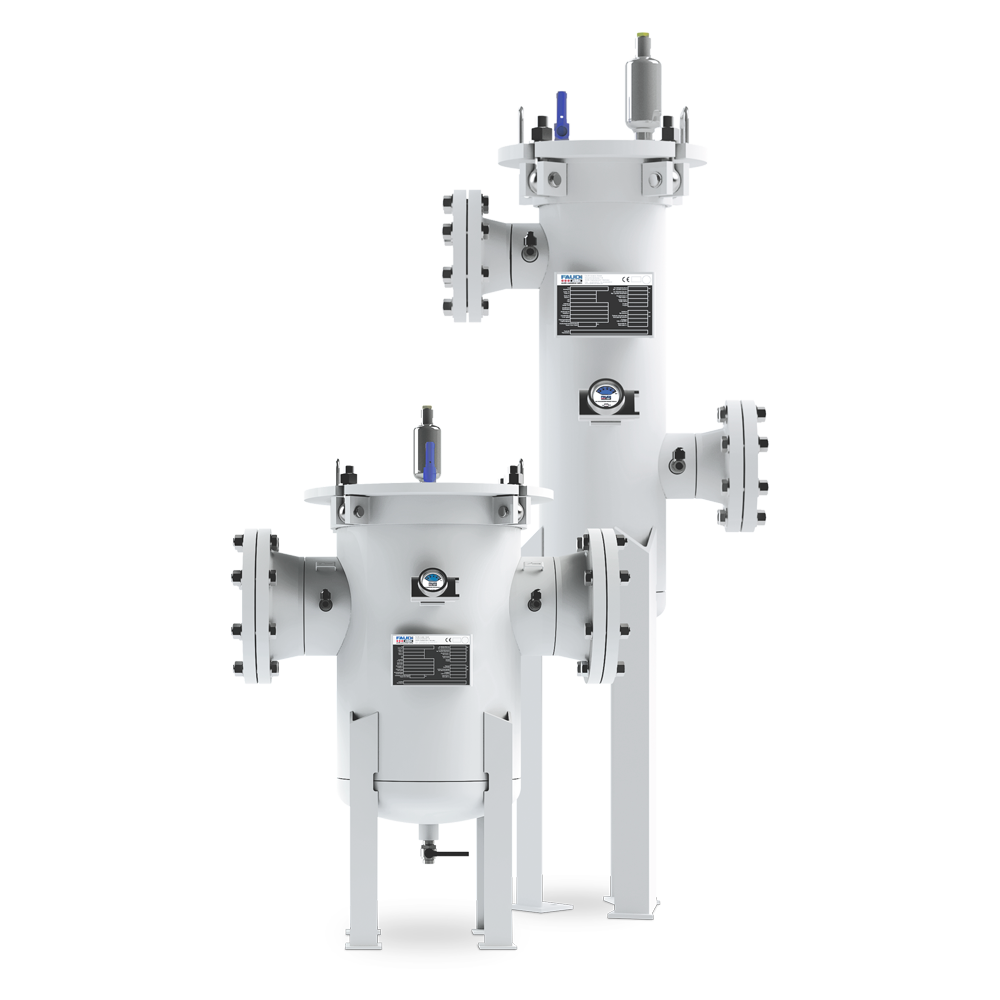

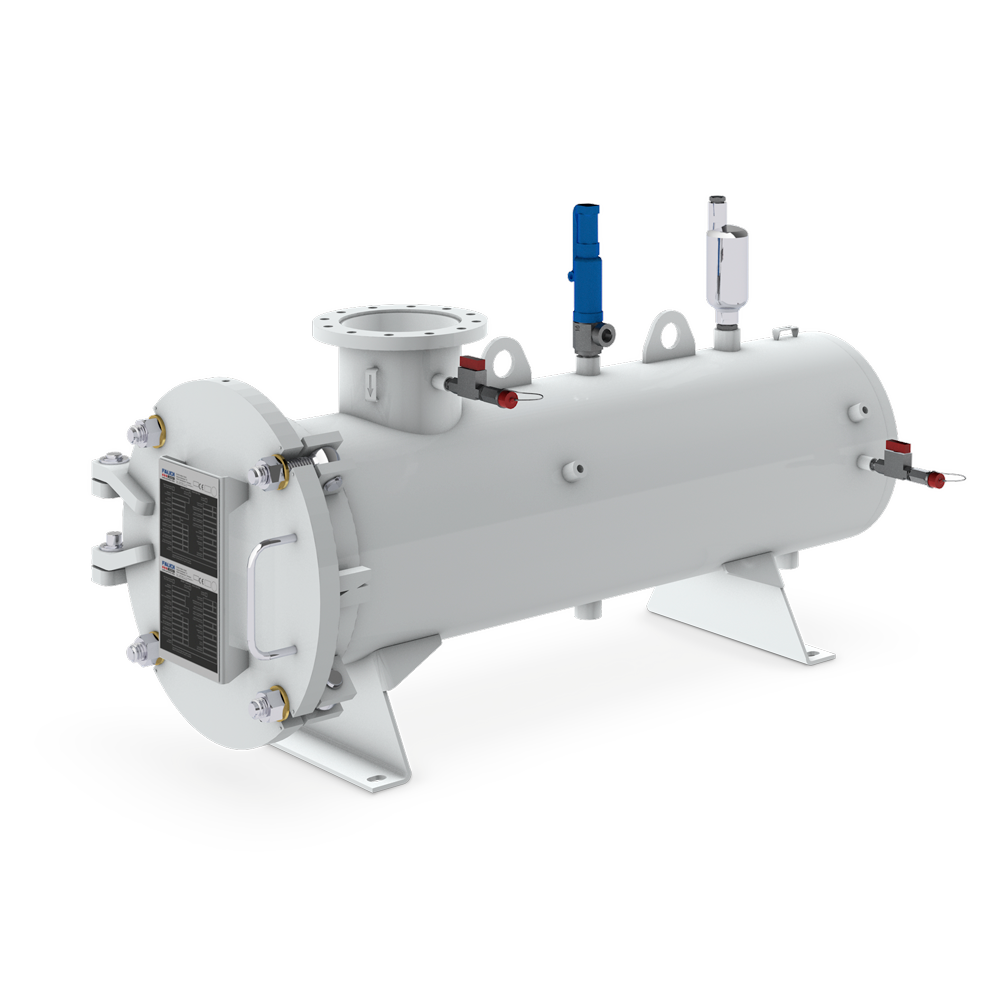

Filter/Water Separator

FAUDI Aviation filter/water separators are designed to be compliant with procedural guidelines, applicable legal regulations and requirements of the pressure vessel regulations (AD2000, ASME, and others).

Filter/water separators consist of two-stages designed to remove free water and particulates from aviation fuels at refineries, terminals, fuel depots, tankers, hydrant dispensers and other mobile refuelling equipment. Filter/water separators are intended for use in commercial aviation fuel (defined as category C), military aviation fuel (defined as category M) and military aviation fuel with an additive for thermal stability (defined as category M100).

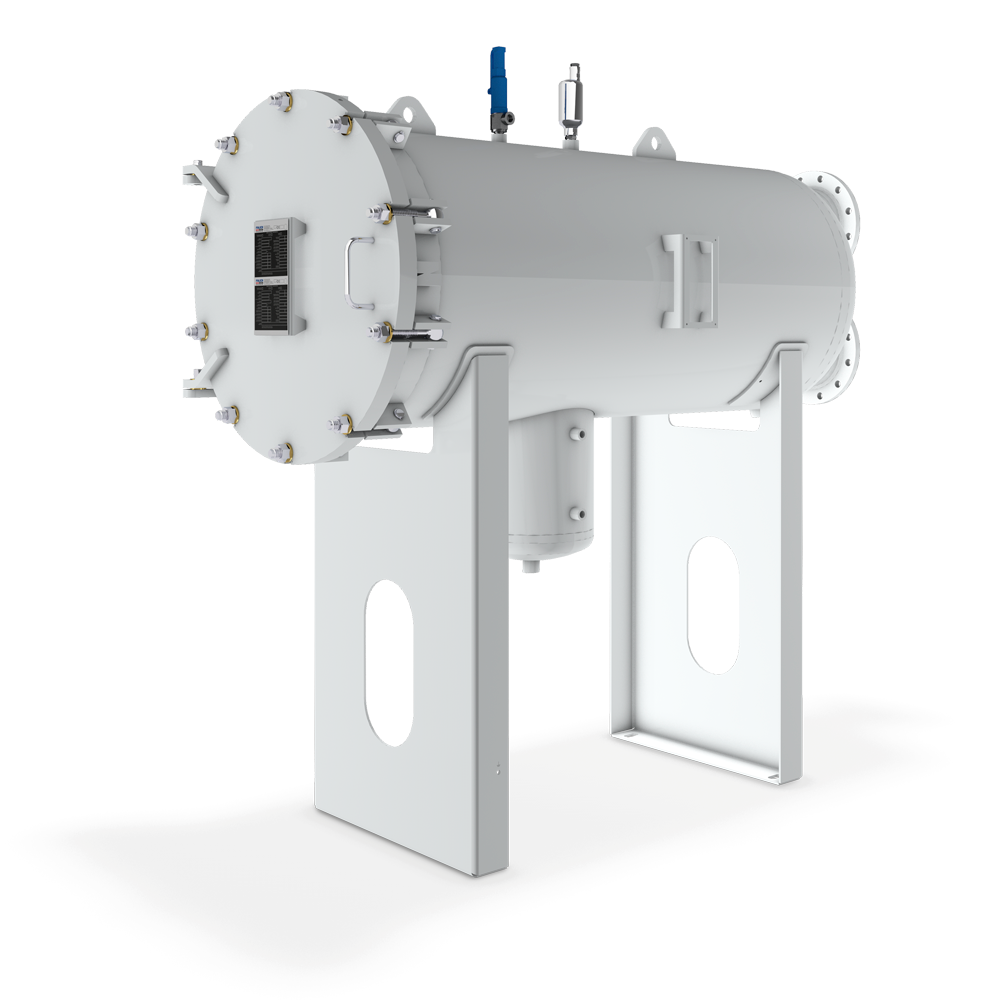

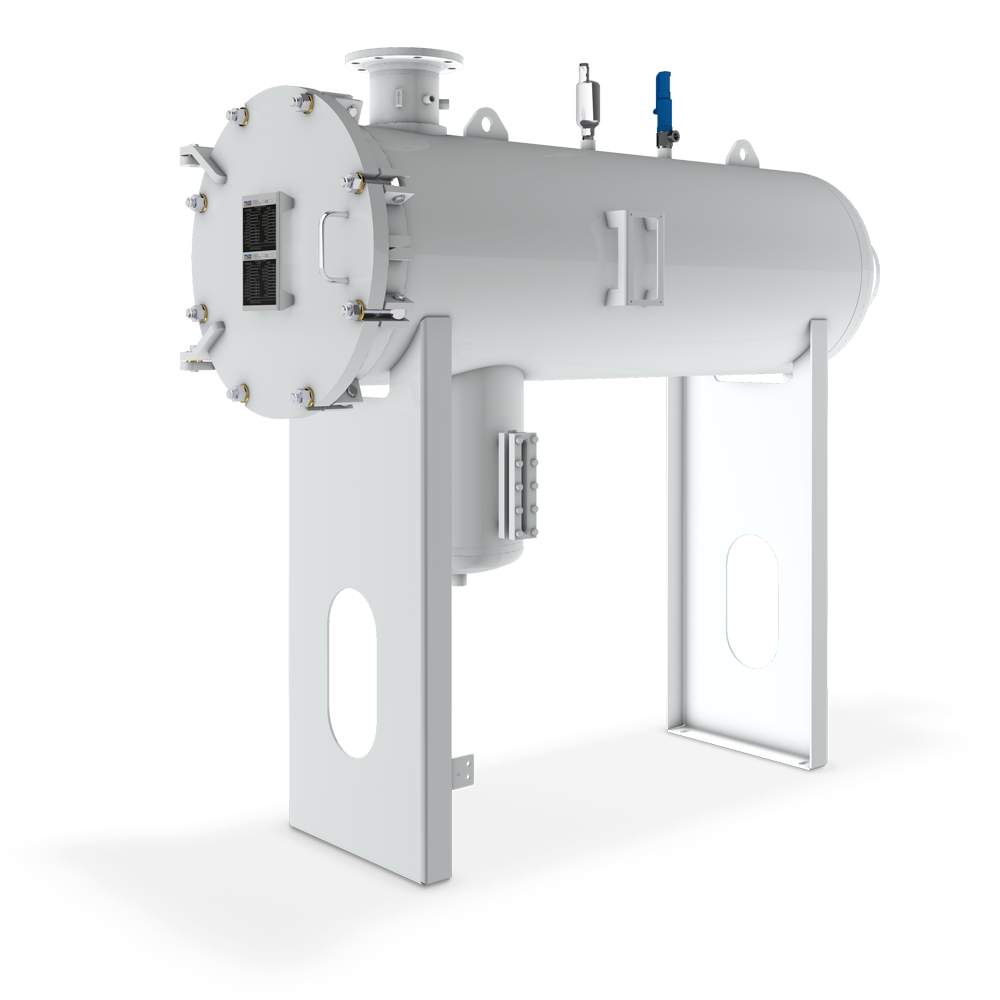

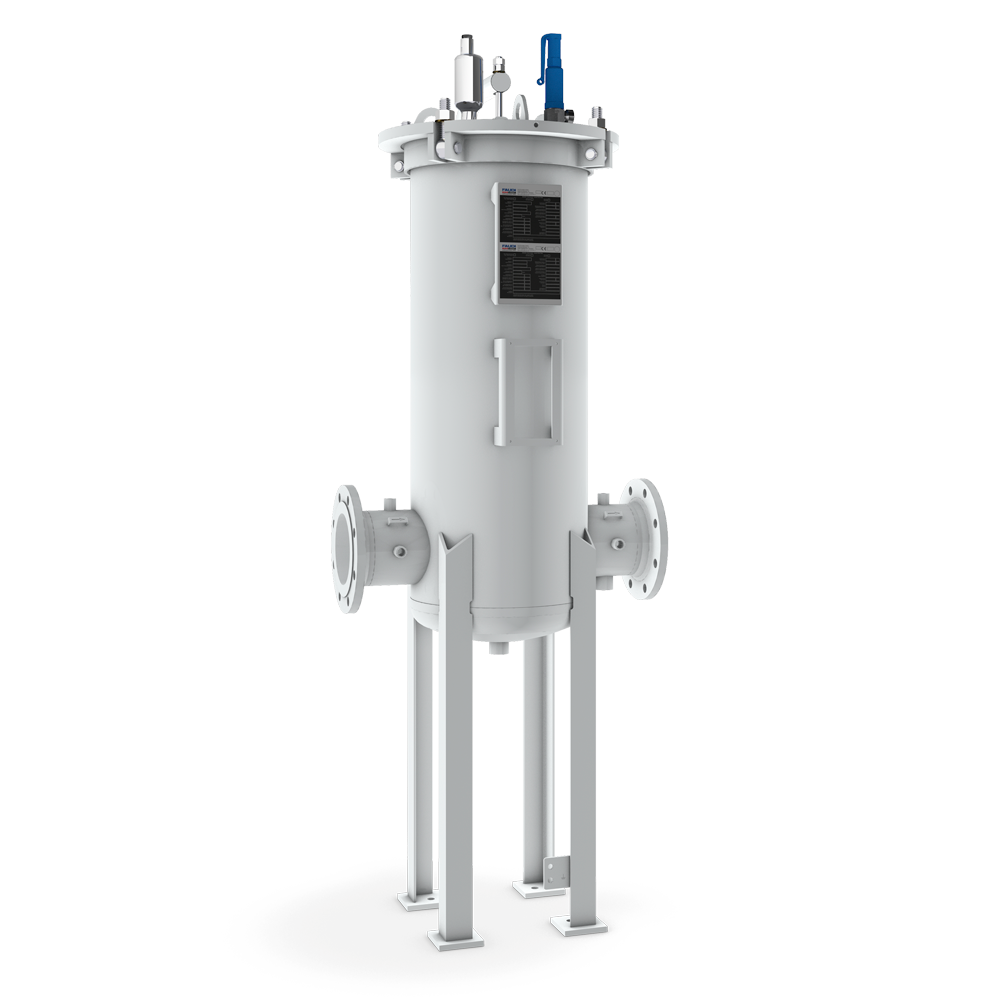

FW10-H Series

Fixed Installation

- EI 1581 6th Edition, Category C, Type S

- Design and construction according to EI 1596

- Design according to AD 2000 (ASME code available upon request)

- Maximum flow rate up to 9500 lpm (2509 USgpm)

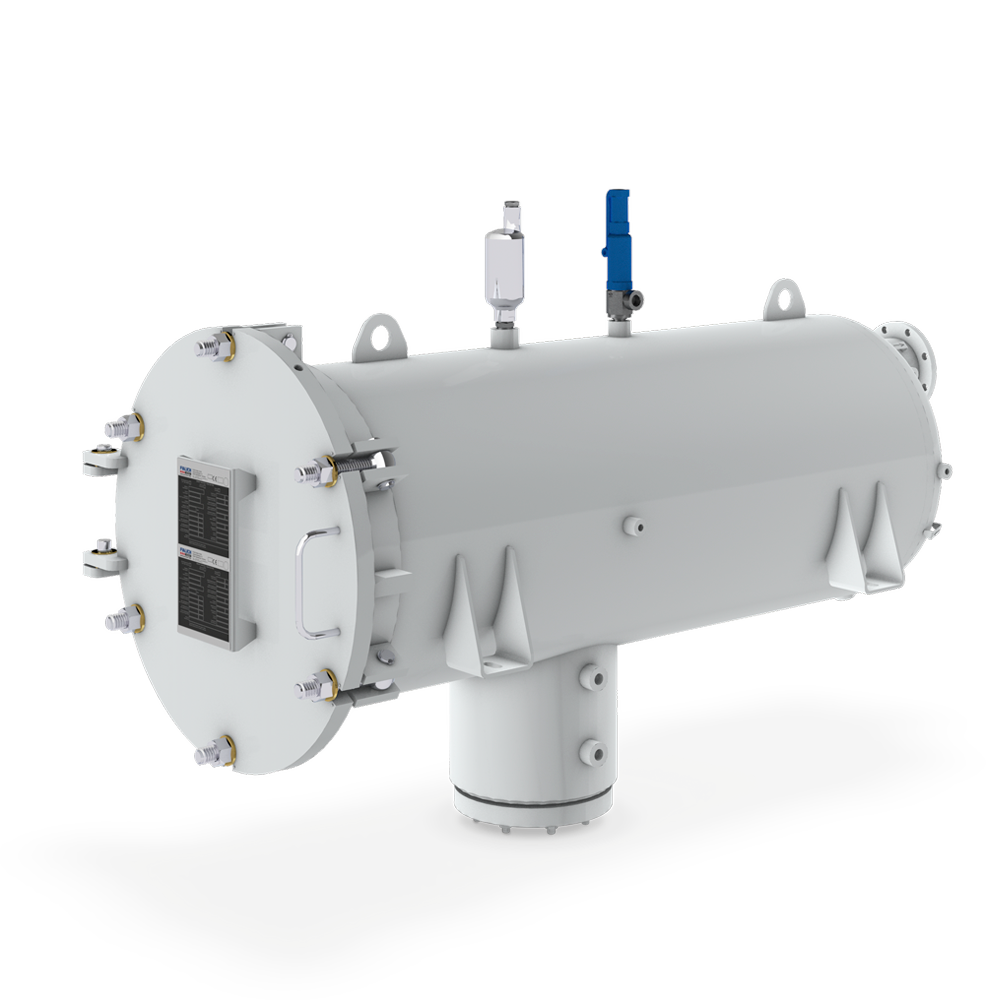

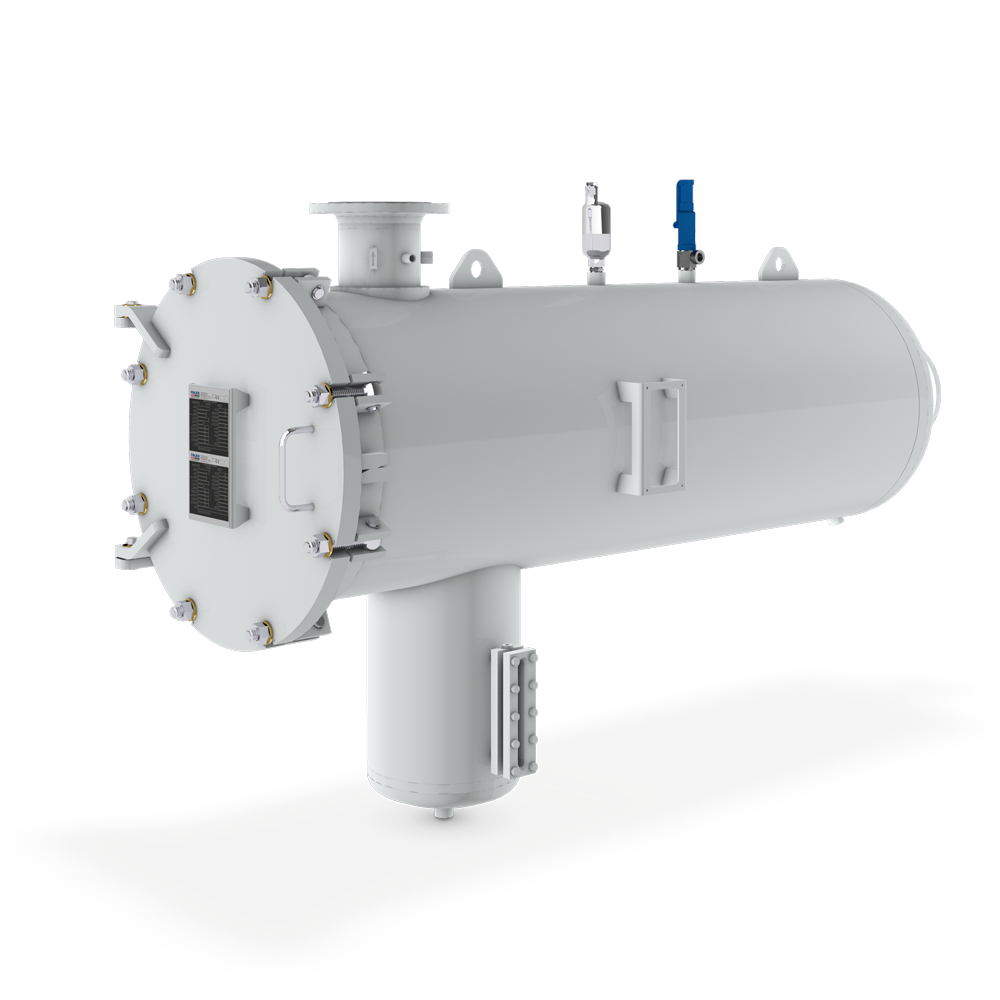

FW10-H-T Series

Mobile Installation

- EI 1581 6th Edition, Category C, Type S-LW

- Design and construction according to EI 1596

- Design according to AD 2000 (ASME code available upon request)

- Maximum flow rate up to 4950 lpm (1307 USgpm)

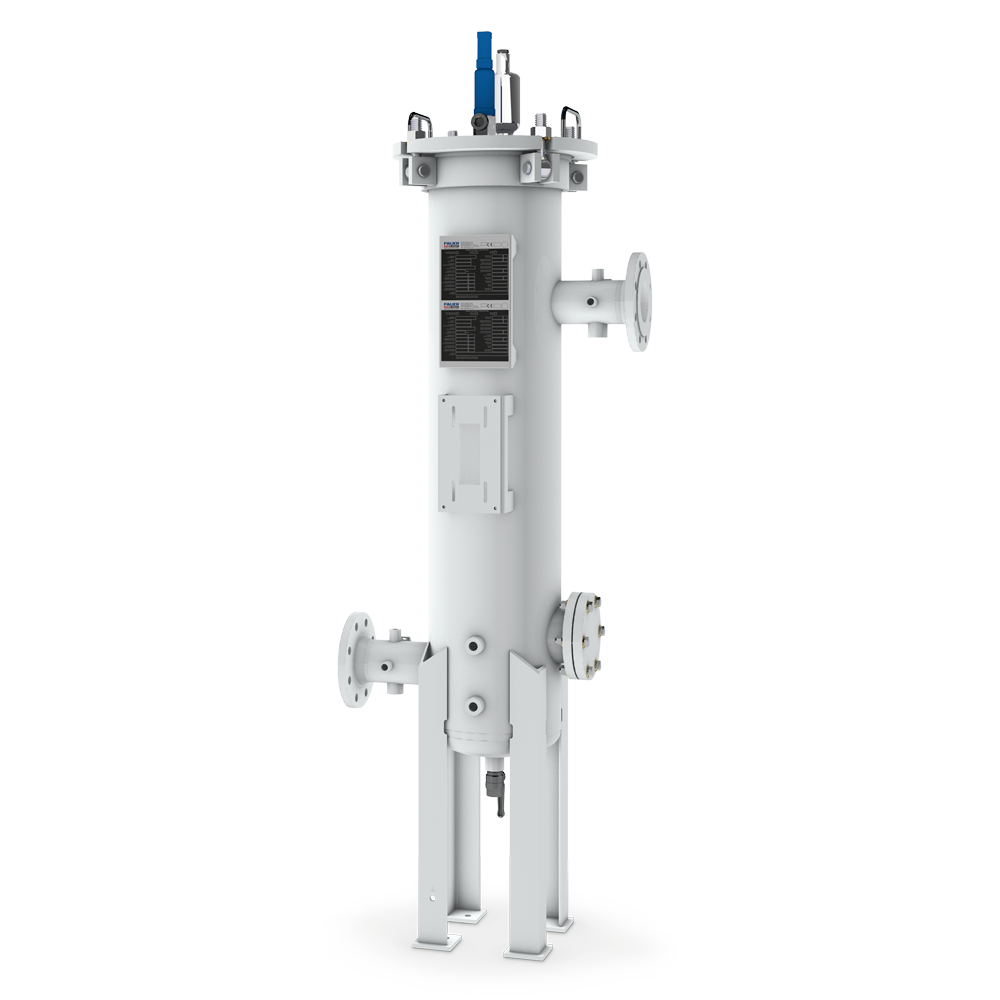

FW10-V Series

Fixed Installation

- EI 1581 6th Edition, Category C, Type S

- Design and construction according to EI 1596

- Design according to AD 2000 (ASME code available upon request)

- Maximum flow rate up to 9500 lpm (2509 USgpm)

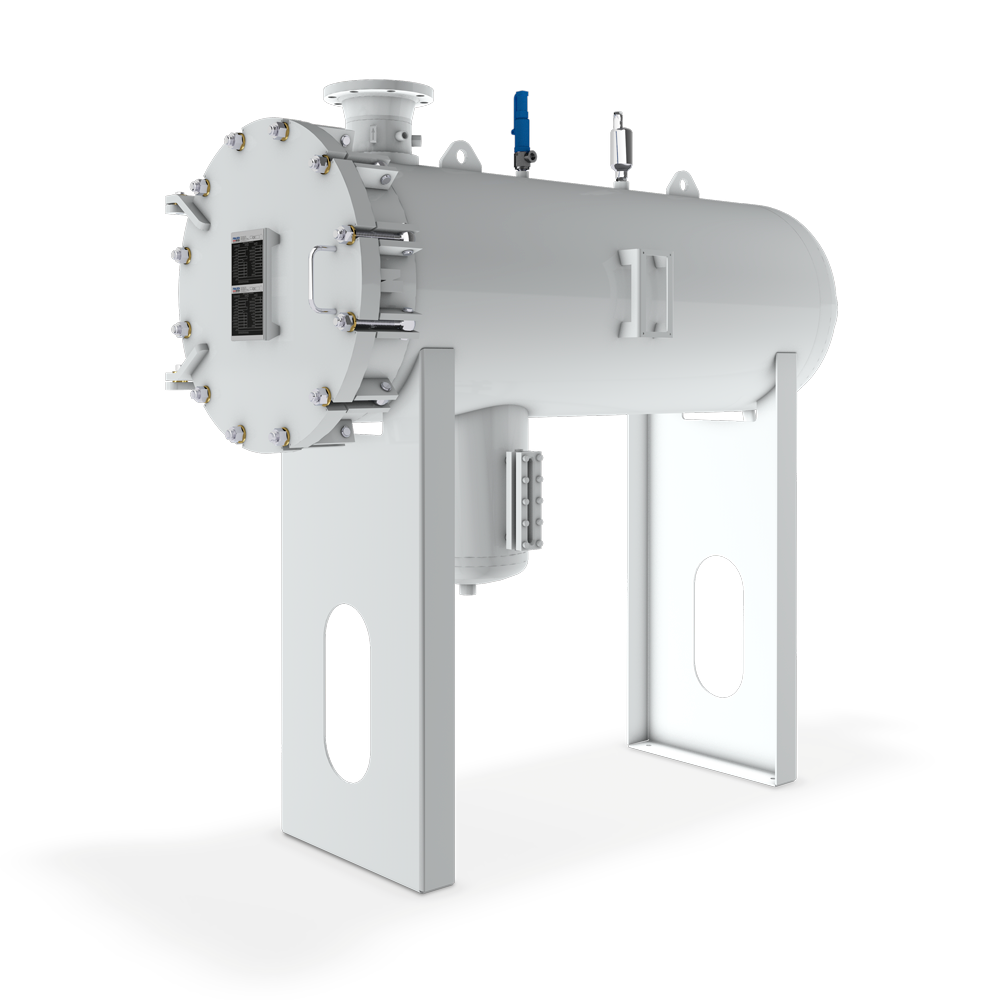

FW24-H-T Series

Mobile Installation

- EI 1581 6th Edition, Category C, Type S-M

- Design and construction according to EI 1596

- Design according to AD 2000 (ASME code available upon request)

- Maximum flow rate up to 4180 lpm (1104 USgpm)

FW6 Series

Fixed Installation

- EI 1581 6th Edition, Category C, Type S

- Design and construction according to EI 1596

- Design according to AD 2000 (ASME code available upon request)

- Maximum flow rate up to 4680 lpm (1236 USgpm)

FW6-T Series

Mobile Installation

- EI 1581 6th Edition, Category C, Type S and S-LW

- Design and construction according to EI 1596

- Design according to AD 2000 (ASME code available upon request)

- Maximum flow rate of Type S up to 3240 lpm (855 USgpm), Type S-LW up to 4500 lpm (1188 USgpm)

FWE Series

Fixed Installation

- EI 1581 6th Edition, Category M, Type S

- Design and construction according to EI 1596

- Design according to AD 2000 (ASME code available upon request)

- Maximum flow rate up to 5000 lpm (1320 USgpm)

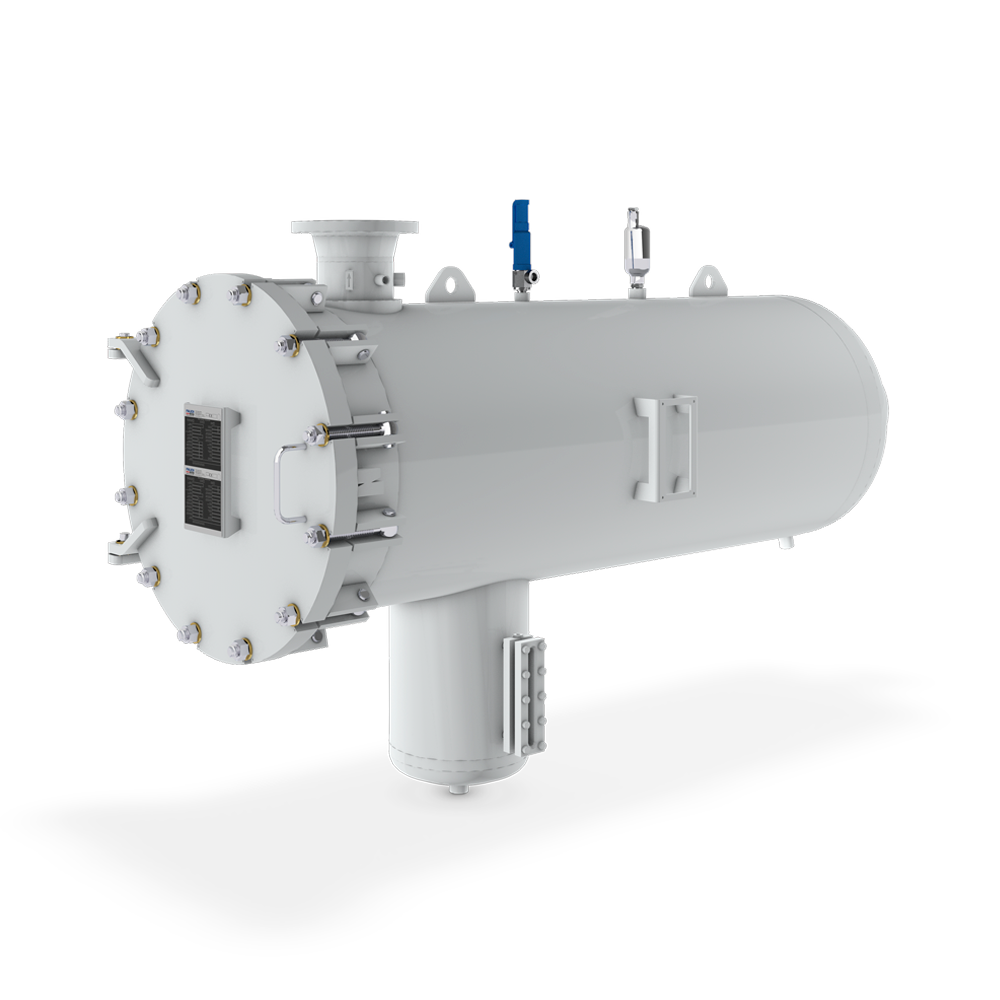

FWE-T Series

Mobile Installation

- EI 1581 6th Edition, Category M, Type S

- Design and construction according to EI 1596

- Design according to AD 2000 (ASME code available upon request)

- Maximum flow rate up to 5000 lpm (1320 USgpm)

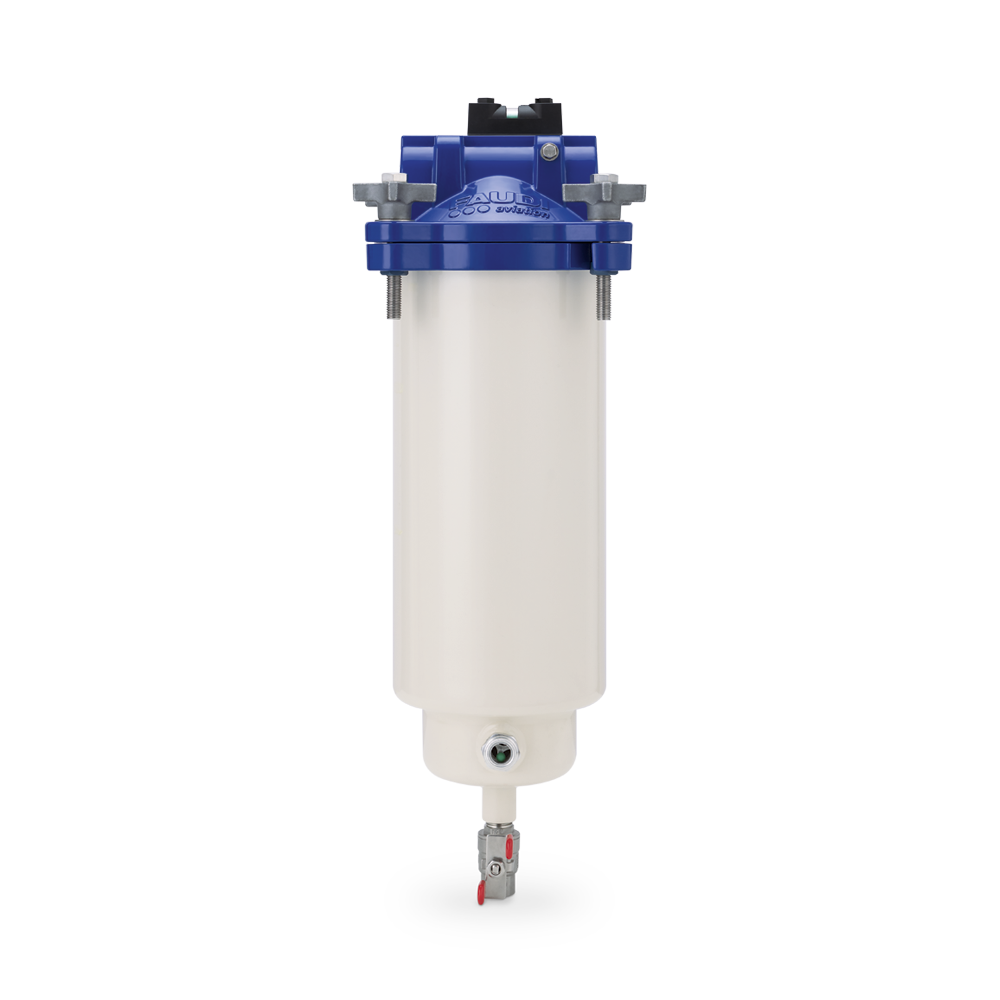

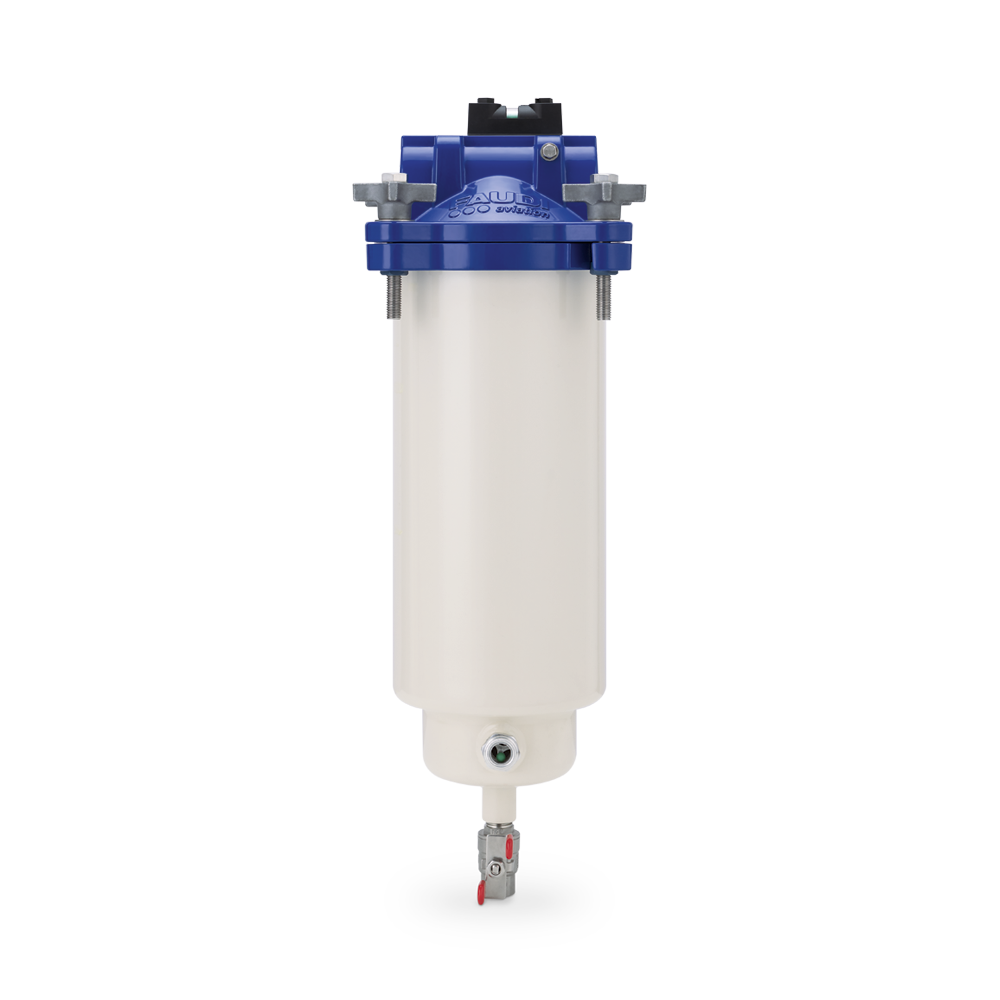

VFH Series

Mobile Installation

The Vertical Filter Housing (VFH) assembly provides two element options to meet the requirements in the aviation fuel filtration industry: Coalescer/Separator and Microfilter (Prefilter).

- Complies to EI specification of each element type

- Maximum flow rate up to 177 lpm (46 USgpm)

FW9-S Series

Fixed Installation

- EI 1581 6th Edition, Category C, Type S

- Design and construction according to EI 1596

- Design according to AD 2000 (ASME code available upon request)

- Maximum flow rate up to 330 lpm (87 USgpm)

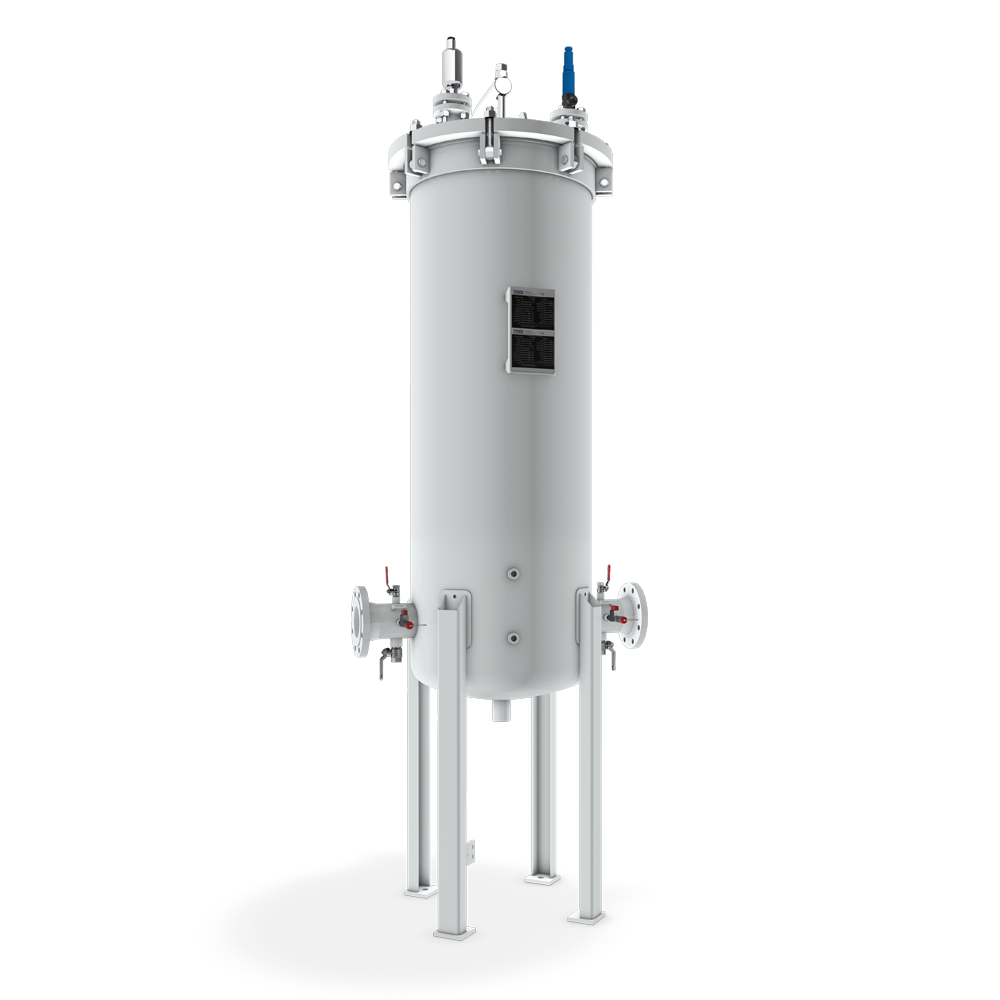

Microfilter

Microfilters are used as pre-filters for the efficient and continuous removal of solids such as rust, sand and other particulates from aviation fuels. FAUDI Aviation microfilters are used in refineries, terminals and airport depots, primarily as prefilters to lengthen the service life of downstream coalescer elements in filter/water separators. FAUDI Aviation microfilters are highly efficient and thus cost effective due to their large filter surfaces area.

FAUDI Aviation Microfilter are designed to be compliant with procedural guidelines, applicable legal regulations and requirements of the pressure vessel regulations (AD2000, ASME, and others).

MF Series

Fixed Installation

- EI 1590 3rd Edition (non-EI compliant filter elements up on request)

- Design and construction according to EI 1596

- Design according to AD 2000 (ASME code available upon request)

- Maximum flow rate of type 4" filter elements up to 11500 lpm (3037 USgpm), type 6" filter elements up to 13100 lpm (3460 USgpm)

VFH Series

Mobile Installation

The Vertical Filter Housing (VFH) assembly provides two element options to meet the requirements in the aviation fuel filtration industry: Coalescer/Separator and Microfilter (Prefilter).

- Complies to EI specification of each element type

- Maximum flow rate up to 177 lpm (46 USgpm)

Dirt Defence Filter Vessel

Dirt Defence Filter Vessels are designed to be compliant with procedural guidelines, applicable legal regulations and requirements of the pressure vessel regulations (AD2000, ASME, and others).

DDFV Series

Mobile Installation

- EI 1599 2nd Edition

- Design and construction according to EI 1596

- Design according to AD 2000 (ASME code available upon request)

- Maximum flow rate up to 4600 lpm (1215 USgpm)

Clay Treater and Sieve Basket Strainer

Clay Treaters are designed to remove surface active agents (surfactants) from aviation fuels. Contaminants of this kind can be present in the fuel from refinery carry over or from cross-contamination in multi-product pipelines. Clay Treaters are usually installed in front of filter/water separators.

Screen Basket Filters are intended for use in aviation fuels for bulk filtration upstream of microfilters. A Screen Basket Filter consists of a perforated screen basket of carbon steel, stainless steel or other materials, depending on the fuels or gases to be filtered.

Clay Treater C Series

Fixed Installation

- Design according to AD 2000 (ASME code available upon request)

- Maximum flow rate up to 3300 lpm (871 USgpm)

Sieve Basket Strainer SKF

Fixed Installation

- Design according to AD 2000 (ASME code available upon request)

- Filter area of SKF Type from 11 to 37.500 cm², Type 21 up to 1,6 m²